Aluminium launching is the procedure of serving steel that is melted into a form to make an aspect of a preferable look. Cast is used in many different businesses to make many parts. Aluminium is powerful steel with excellent deterioration resistance. The chemical qualities of light weight steel die launching must be taken into account for welding. Some of the key comprise the reducing temperature, colour change, nonmagnetic characteristics, electrical qualities and thermal qualities.

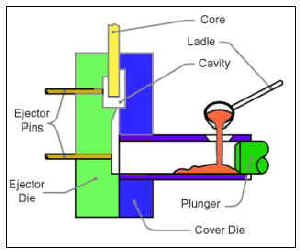

In the basic die casting process, molten metal is injected into the die and then the two parts of create the finished Casting shuts the die are stamped close by product. There are two kinds of Cold Chamber, Hot Chamber and Casting Machines. This is an extremely cost-effective, efficient, and exact method of producing metal parts and is used, as noted above, for a broad range of products by a great variety of sectors.

Manual floor molding can use resin patterns and aluminum patterns in China. When it comes to iron castings with substantial annual demand or complex structures, the aluminum designs will probably be critical. Aluminum designs are more economical than iron patterns. One set of aluminum patterns is generally 1000 to 2000 USD. Nonetheless, in the event the iron casts have high requirements to the inside surfaces, which means the sand centers have to be done by iron patterns, then the overall routine prices will be higher than this price range.

Use a wire brush to remove sheetrock mud or any mud from the outside of the facet. Excessive light steel can be ground or cut away, and the exterior may be smoothed if preferred.

The Ridgid R8823 impact driver is only packaged with a single-ended impact bit. There is no battery or charger included in the package, which means you'll need to get one or use. The tool was assembled for maximum durability but is still backed up by a warranty that was good. The impact driver is backed by a three-year limited please click the up coming document guarantee.

The wax is then assembled with other waxes on a tree. Depending on the size of the component, each tree becomes 10 - 200 pieces. It is dipped in 5 layers of ceramic slurry, after the tree is fully assembled.

These autos introduced in the late 50's. Because metal and plastic were joined in the early days, that was really an interesting interval. Before becoming all linked web-site plastic a plastic body shell using an alloy frame. Jada toys and playthings will stay in the market for decades to come, as they are able to still be sold at an affordable cost as gifts or play things for children rather than as china doll for grownups.